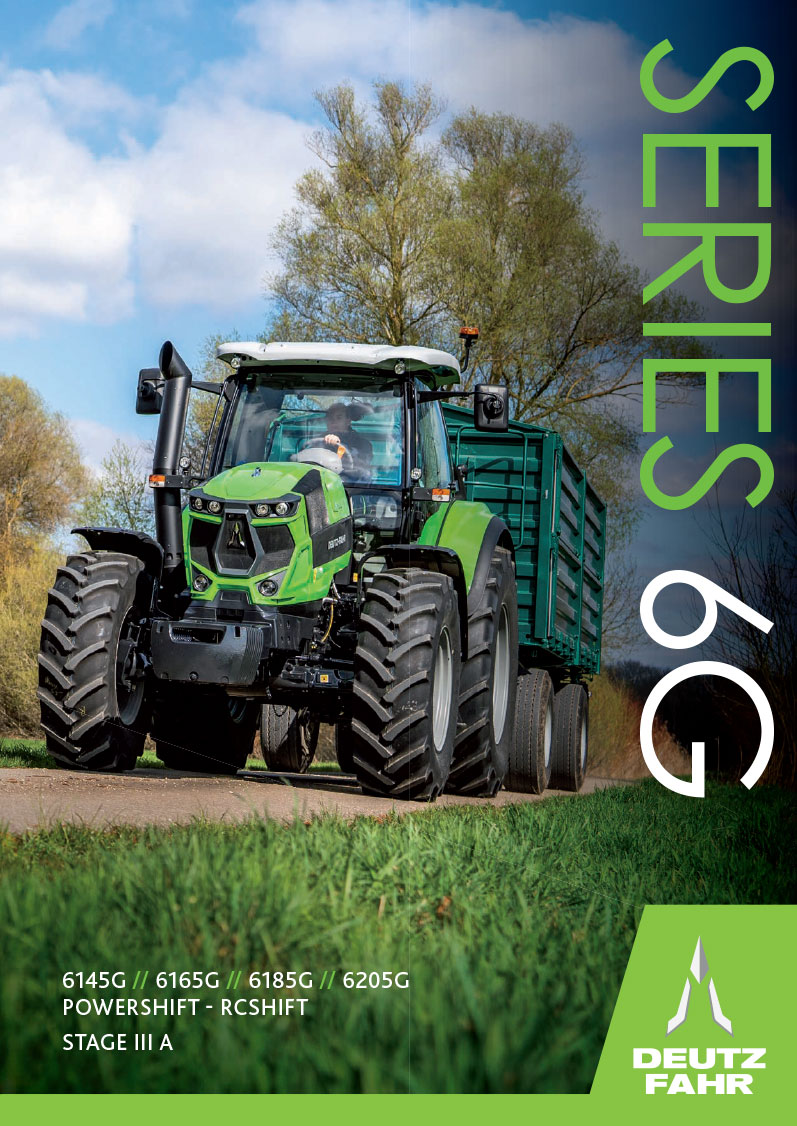

6G SERIES

Power, Efficiency, and Reliability

With five models ranging from 145 to 200 HP, the 6-cylinder DEUTZ-FAHR 6G Series is built for farmers who demand high productivity, low operating costs, and simple, reliable performance. These tractors deliver exceptional efficiency and ease of use, backed by straightforward maintenance and proven technology.

At their core are Stage IIIA-compliant Deutz 6-cylinder engines, renowned for their durability and fuel efficiency. Paired with highly efficient ZF transmissions and class-leading hydraulic systems, they offer outstanding all-round performance in any application.

The 6G Series combines robust engineering, modern design, and German precision, making it a perfect blend of power, reliability, and value — a tractor that works as hard as you do