The demands made of a modern, infinitely variable transmission are clear: high tractive force with a low hydrostatic involvement, maximum economy and most importantly, user convenience. The transmission of the Agrotron TTV, which DEUTZ-FAHR developed in collaboration with ZF, has entered new dimensions in stepless transmission technology: Practical operating convenience, maximum efficiency and exemplary economy are the main characteristics.

High mechanical efficiency

The unsurpassed efficiency of a stepless transmission is possible due to the use of state-of-the-art technology. In each of the four working ranges the maximum driving power is mechanically transferred. The hydrostatic share is reduced to a minimum, ensuring maximum efficiency, without hydraulic losses at low speeds during fieldwork.

Intelligent transmission design

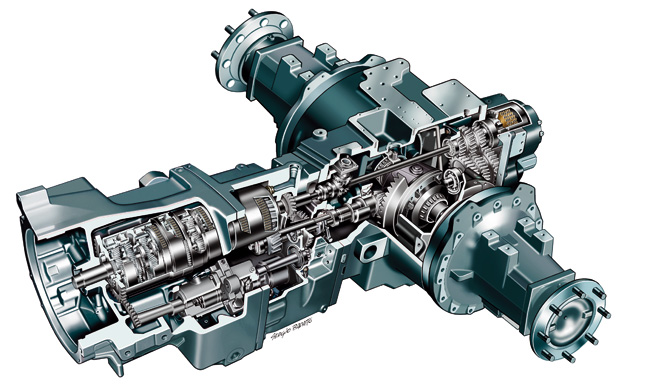

The stepless, performance-graded transmission of the Agrotron TTV comprises four main components - planetary transmission, the hydrostatic unit, the shuttle clutches and the electronic control unit. The high degree of efficiency is ensured due to the direct power fl ow from engine to the, planetary transmission, shuttle transmission, PTO and axle.

Infinitely variable from 0 to 50 km/h

The transmission comprises four planetary trains. The entire speed range is practically divided into the four working ranges by the planetary trains. The speed is steplessly varied within each working range by a hydrostatic unit. This gives you the possibility of infinitely variable travel speeds from 0 - 50 km/h, using the combination of the planetary trains and the hydrostatic unit. The planetary trains are inter-connected by maintenance-free long life multi-plate clutches.

Automatic working

Nothing is simpler - start up, pull away and off to work! In automatic mode the Agrotron TTV offers maximum convenience for all jobs and applications without complex programming. Transport and field work are mastered with ease. The selection of the required speed is performed precisely with the PowerComV or fast adjustment feature. The engine speed is adapted by the engine electronics which ensures the right speed for all load conditions. The driver therefore always works in the economical range. Advantages of automatic mode: Simple manoeuvring and convenience during driving and working with the same standard of comfort as a car. The Tempomat cruise control function is an effective supplement for many jobs and relieves the strain on the driver. Auto, ECO or Power: The driver decides! The driver can programme the basic settings of automatic mode and determine the range within which the engine speed is varied depending on the job.

PTO mode

This mode is automatically activated when the PTO is switched on, and permits economical operation of the Agrotron TTV at constant engine speeds. The required engine speed can be set or adjusted with the EMC button or the electronic manual throttle. The Tempomat cruise control function is also available. Advantage: TheAgrotron TTV adjusts directly and conveniently to working and operating conditions at every engine speed.

Manual mode

The driving pedal is solely an accelerator pedal controlling the engine speed. The speed can be infi nitely varied from 0 - 50 km/h with the PowerComV. Thelowest speed is a super-slow 47 m/h.

Active parking control

This function allows you to reliably keep the transmission and tractor stationary irrespective of the slope, hill or respective load simply by removing your foot off the drive pedal, without actuating the service or trailer brake. You are therefore able to safely and conveniently stop, hold and drive off again in any condition and direction

With the Agrotron TTV you get a pressure and volume-controlled hydraulic system (Load-Sensing) with a pump flow capacity of up to 120 l/min and a system pressure of 200 bar. The closed centre system uses an axial piston, variable displacement pump controlled by hydraulic demand. The system pressure drops as oil flow is called for; only then does the variable displacement pump automatically provide more oil so that the pressure demanded is maintained. The consumer with the highest pressure requirements determines the current system pressure.

With the Agrotron TTV you get a pressure and volume-controlled hydraulic system (Load-Sensing) with a pump flow capacity of up to 120 l/min and a system pressure of 200 bar. The closed centre system uses an axial piston, variable displacement pump controlled by hydraulic demand. The system pressure drops as oil flow is called for; only then does the variable displacement pump automatically provide more oil so that the pressure demanded is maintained. The consumer with the highest pressure requirements determines the current system pressure..jpg?w=245&h=160)

.jpg?w=245&h=160)