6 DT SERIES

THE BEST TECHNOLOGY MIX IS NOW COMPACT FROM 126 TO 136 HP

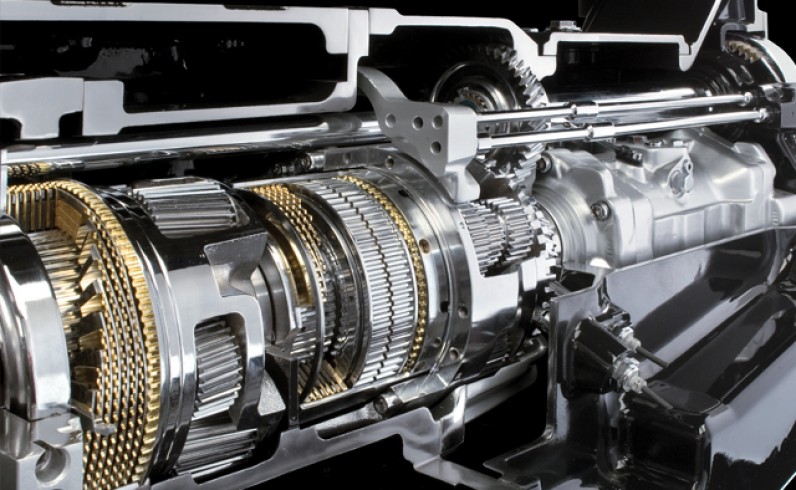

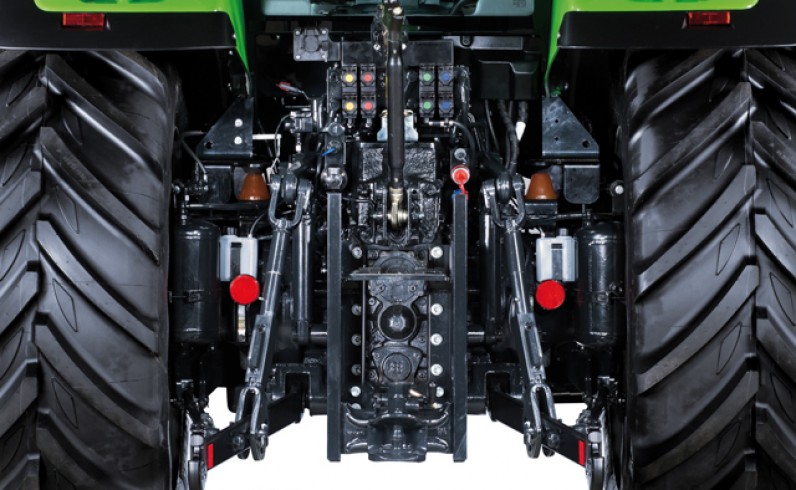

The new 6 Series provides the best technology mix in its class. DEUTZ-FAHR has expanded the series with two compact, four-cylinder tractors in the low to mid horsepower category: the 6130 and 6140, which are available with TTV or Powershift transmissions. From ploughing, sowing and cultivating to transporting, harvesting crops and front loader work – the new 6 Series tractors are as versatile as your daily work is varied. Maximum manoeuvrability, supreme efficiency and unparalleled operating comfort are trademark features of the new 6 Series. The modern bonnet design, LED light package and 8" iMonitor in the cab all blend in seamlessly with the complete model range. Like the existing 6 Series, the new, compact four-cylinder tractors come with powerful hydraulic systems as well as a range of hydraulic attachment points at the front and rear. Ultra-efficient Deutz TCD 3.6 engines (Stage IV) with an output from 126 to 136 HP (92.7 to 101 kW) ensure characteristically high performance and low fuel consumption. A variety of equipment options are available. The spacious cab provides the high level of operating and driving comfort that DEUTZ-FAHR has become known. With the six new models in the range, DEUTZ-FAHR has added even more options to the technology mix. Enterprises looking for a compact model that offers a wide range of features as well as comfort and convenience are guaranteed to find a perfectly suitable all-round tractor that matches their work profile and individual requirements.